Optimizing Supply Chains with EDI

In our globalized economy, companies must effectively manage the trade of goods and services from suppliers to customers to remain competitive. This includes tasks like inventory management, order processing, and transportation. But how can companies optimize their supply chain to improve efficiency, reduce costs, and boost consumer satisfaction?

One solution is EDI integration. EDI, or Electronic Data Interchange, plays a vital role in optimizing supply chain management by automating these activities and providing real-time visibility into the supply chain. Furthermore, implementing EDI transactions can yield significant financial benefits, with studies indicating that switching to EDI can reduce transaction costs by at least 35%.

How EDI Can Optimize the Supply Chain

Procurement

Implementing EDI in the supply chain enables the automation of the entire procurement process. It facilitates seamless communication between buyers and suppliers by electronically exchanging purchase orders, invoices, and other relevant documents. This automation improves efficiency by reducing manual data entry errors and eliminates the need for paper-based processes. EDI integration allows for real-time tracking of shipments, ensuring timely delivery of orders. Overall, these benefits help to improve efficiency, reduce costs, and enhance the accuracy of the procurement process.

Manufacturing

EDI integration can greatly impact the manufacturing process by automating critical tasks such as sending production orders and tracking inventory levels. By electronically transmitting production orders, manufacturers can efficiently initiate and manage the production cycle. This eliminates the need for manual order processing, reduces lead times, and improves production scheduling accuracy.

Integrating EDI with inventory management systems also allows real-time tracking of inventory levels, enabling timely replenishment and minimizing stockouts. By leveraging EDI in manufacturing, businesses can improve efficiency, reduce costs, and keep production on schedule.

Distribution

EDI integration in the supply chain offers significant advantages in the distribution phase. Through EDI, businesses can automate various distribution processes, like shipping products and tracking deliveries. By electronically exchanging shipment information with carriers and logistics partners, companies can achieve better visibility and control over their distribution operations.

Real-time tracking of deliveries ensures that products reach customers on time, reducing delays and improving customer satisfaction. Furthermore, EDI integration in distribution helps streamline the order fulfillment process, minimizes errors, and reduces costs associated with manual data entry and paper-based documentation.

Additional Benefits of EDI for Supply Chain Management

Improved efficiency:

EDI integration can significantly improve the efficiency of supply chain management by automating various tasks, such as order processing and inventory management. This automation reduces manual effort, minimizes processing time, and enhances overall productivity.

- Order processing: Instead of manually entering order details, EDI allows for the seamless electronic exchange of orders between trading partners. This automation eliminates errors and delays associated with manual data entry, leading to faster order processing and improved efficiency.

- Inventory management: With EDI integration, real-time inventory updates can be exchanged electronically between suppliers and retailers. This enables better inventory visibility, accurate demand forecasting, and improved coordination, resulting in optimized stock levels and reduced holding costs.

Reduced costs:

EDI integration helps reduce costs associated with supply chain management by eliminating the need for manual data entry, paper-based transactions, and associated errors. These cost reductions also lead to improved accuracy and efficiency.

- Data entry: Manual data entry is time-consuming and prone to errors. By automating data exchange through EDI, businesses can eliminate the need for manual entry, reducing labor costs and minimizing data-related errors.

- Paper-based transactions: Paper-based transactions require printing, postage, and physical storage. By replacing these with electronic transactions facilitated by EDI, companies can save costs associated with paper, printing, mailing, and storage space.

Improved accuracy:

EDI integration enhances the accuracy of supply chain management by reducing the risk of errors caused by manual data entry, leading to increased customer satisfaction and reduced costs.

- Manual data entry errors: EDI completely eliminates manual entry errors by enabling the direct transfer of data between systems, ensuring accurate and consistent information across the supply chain.

- Invoice reconciliation: EDI enables automated matching of invoices with corresponding purchase orders and shipment notices. This reconciliation process helps identify discrepancies early, minimizing payment errors and disputes.

Improved visibility:

EDI integration enhances supply chain visibility by providing real-time information on inventory levels, shipments, and orders. This visibility improves decision-making and helps prevent stockouts.

- Shipment tracking: Through EDI, businesses can receive real-time updates on the status of shipments, including estimated arrival times, potential delays, and proof of delivery. This information allows for proactive management and effective communication with customers.

- Inventory visibility: By exchanging inventory data electronically, companies gain accurate and up-to-date visibility into stock levels, enabling better demand planning and reducing the risk of stockouts or overstocking.

Enhanced collaboration:

EDI integration facilitates enhanced collaboration with suppliers and partners by providing a common platform for exchanging data. This improves communication and efficiency.

- Supplier coordination: EDI allows for seamless sharing of production forecasts, inventory levels, and delivery schedules between manufacturers and suppliers. This shared information enables suppliers to align their production and delivery schedules accordingly, improving overall supply chain coordination.

- Partner connectivity: By integrating EDI with logistics service providers, businesses can achieve seamless data exchange for transportation management, such as tracking, routing, and delivery confirmation. This collaboration helps optimize logistics operations and improve customer service.

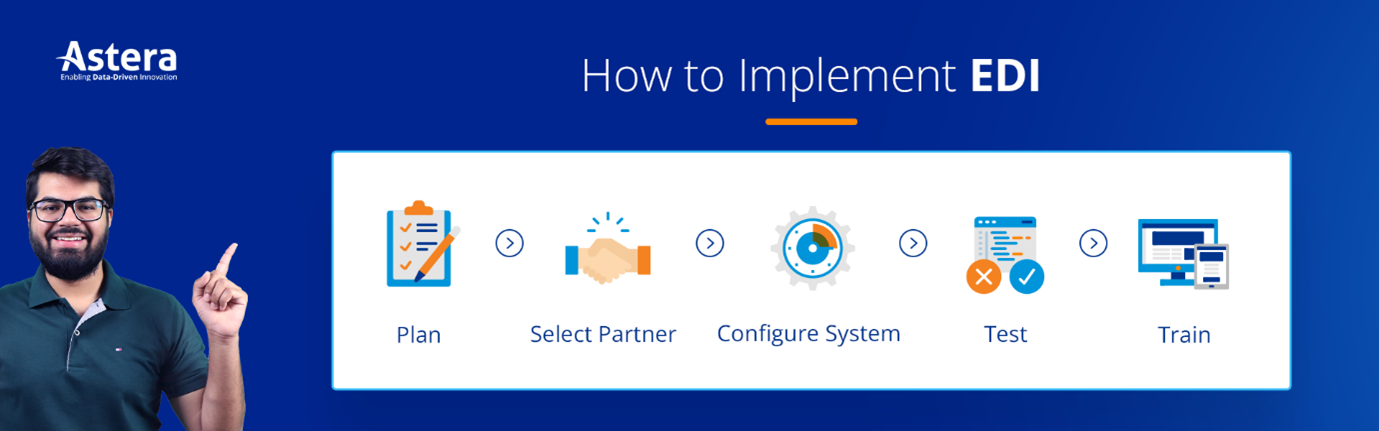

How to Implement EDI for Supply Chain Management

The steps involved in implementing EDI in supply chain can vary depending on the specific needs of the business. Some common steps include:

- Plan: The first step is to develop a plan for EDI integration. This plan should include the following:

- Goals: Clearly define the objectives and benefits you aim to achieve by integrating EDI.

- Scope: Identify the specific systems and processes that will be integrated through EDI.

- Resources: Determine the necessary human resources, time allocation, and financial investment required for a successful integration.

- Timeline: Set a realistic target date for completing the EDI integration, providing a clear timeframe for efficient management of supply chains and alignment among stakeholders.

- Technical Security: Identify the data security requirements to ensure secure B2B data exchange.

- Select a Partner: If you choose to partner with an EDI service provider, it is important to select the right partner with the necessary experience, expertise, and resources to help you implement EDI integration successfully.

- Configure the System: Once you have selected a partner, you will need to configure the EDI system. This process will involve setting up the system to communicate with your trading partners and to exchange data in the correct format.

- Test: Once the system is configured, you will need to test it to ensure that it is working properly. This testing should include a test with your trading partners to ensure that they are able to exchange data with you.

- Train: Once the system is tested, you will need to train your employees to use it. This training should include instruction on how to enter data into the system, how to view data from the system, and how to troubleshoot problems with the system.

Final Word

Integrating EDI into the supply chain management process is a strategic imperative for businesses seeking operational excellence, cost savings, and customer satisfaction. By automating critical tasks, improving efficiency, reducing errors, and providing real-time visibility, EDI integration optimizes procurement, manufacturing, and distribution processes. Embracing EDI integration positions companies at the forefront of supply chain optimization, enabling them to thrive in the dynamic and competitive global economy.

Astera AI Agent Builder - First Look Coming Soon!

Astera AI Agent Builder - First Look Coming Soon!